Roof Pro sends several crews to this big flat roof on a building that’s home to several apartment dwellers on Fire Island. We does not use TORCH DOWN roofing methods for flat roof installations. Instead we use a great quality adhesive to bond the roof material on the top of the building. It’s much safer than applying a torch with direct heat to a persons home. Even if the installer doesn’t set a fire, what you have is melted tar on your roof. This stuff smells and is a caustic and possibly poisonous to your health in the long run.

When attacking such a large roof, we have to go by the local ordinance of trash removal and dust reduction.

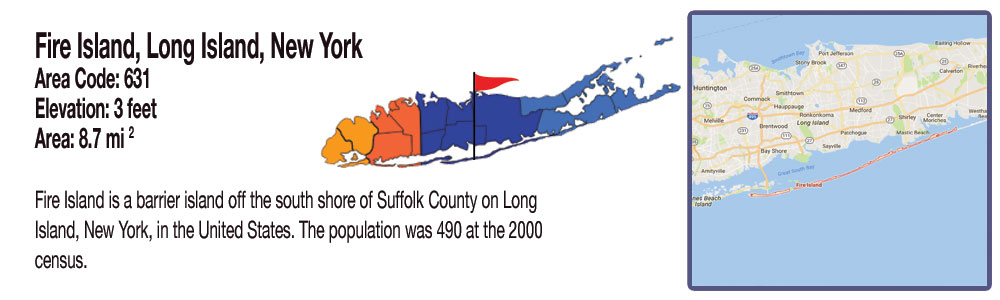

The crew sets up a debris chute that directly empties in to a large dumpster that was hauled in earlier the day before. We do this according to town rules and to keep the place reasonably clean with out roof scrapes, wood pieces and nails flying all over the place. This is a vacation area in Long Island, New York, most people are wearing sandals or are bare foot. We have to be aware of not scattering junk everywhere.

The roads are narrow and hard to navigate on Fire Island, so for the most part we took the ferry across and wagoned our equipment with us. We usually set up a delivery of supplies with a transport company with permits for Fire Island. The job had to be done no matter what.

Roof Pro and the buildings owner has decided to use a EPDM roofing system on this building. The EPDM system is basically a large sheet of rubber that has a thick single layer that would cover large areas of the roof at a time. The owner has little to no traffic that goes on the roof so this system is great for this roof. There are no fire escapes to it or stairways leading to the roof so traffic is almost none at all. EPDM is very puncture prone, especially if there was great amounts of traffic on it. Traffic such as mechanical/HVAC contractors using corrosive chemicals and tar not good on it’s delicate membrane.

Since there was an existing board for this type of install. We spread out the material and used an industrial adhesive to glue it down. We then overlapped the the seams and used primer and seam tapes and corners to make it water and weather proof.

The tricky parts of the roof install was the sky lights scattered around the roof. We had to wrap the ledge or base of the windows to weather proof them. The wrapping of the material had to be adhered to the base corners and then over lapped and taped down. Other things like “T” seams and penetrations are flashed with uncured rubber flashing tapes. These systems have factory produced, cover tapes, pipe boots and pitch pockets for various flashing needs. We can install this roof like a “pool liner” with limited seams and being installed almost in one Hugh piece.

EPDM rubber roofing material is the best system for this building and it looks great when done with it’s almost seamless design.

Commercially this roof is good for large square flat foot roofs that have a very low penetration profile and controlled exposure to the public. In these cases EPDM can be a cost effective system. EPDM is also excellent for high walls, small penthouse roofs or water proofing ductwork.

Our roofs are guaranteed by GAF roofing supplier and by our own Roof Pro contract and warranty. At the the end of the install we cleaned up the sight and had a Forman come back the next day. He’ll show up when it is daytime to look over the job and give it a Roof Pro approval stamp. If there was extra attention needed on the roof a return visit from a Roof Pro crew would have to be scheduled to address it and make the corrections. Although this roof was ready to enjoy it’s weather proof durability for 20+ years.